APPLICATION & FEATURES

Application:

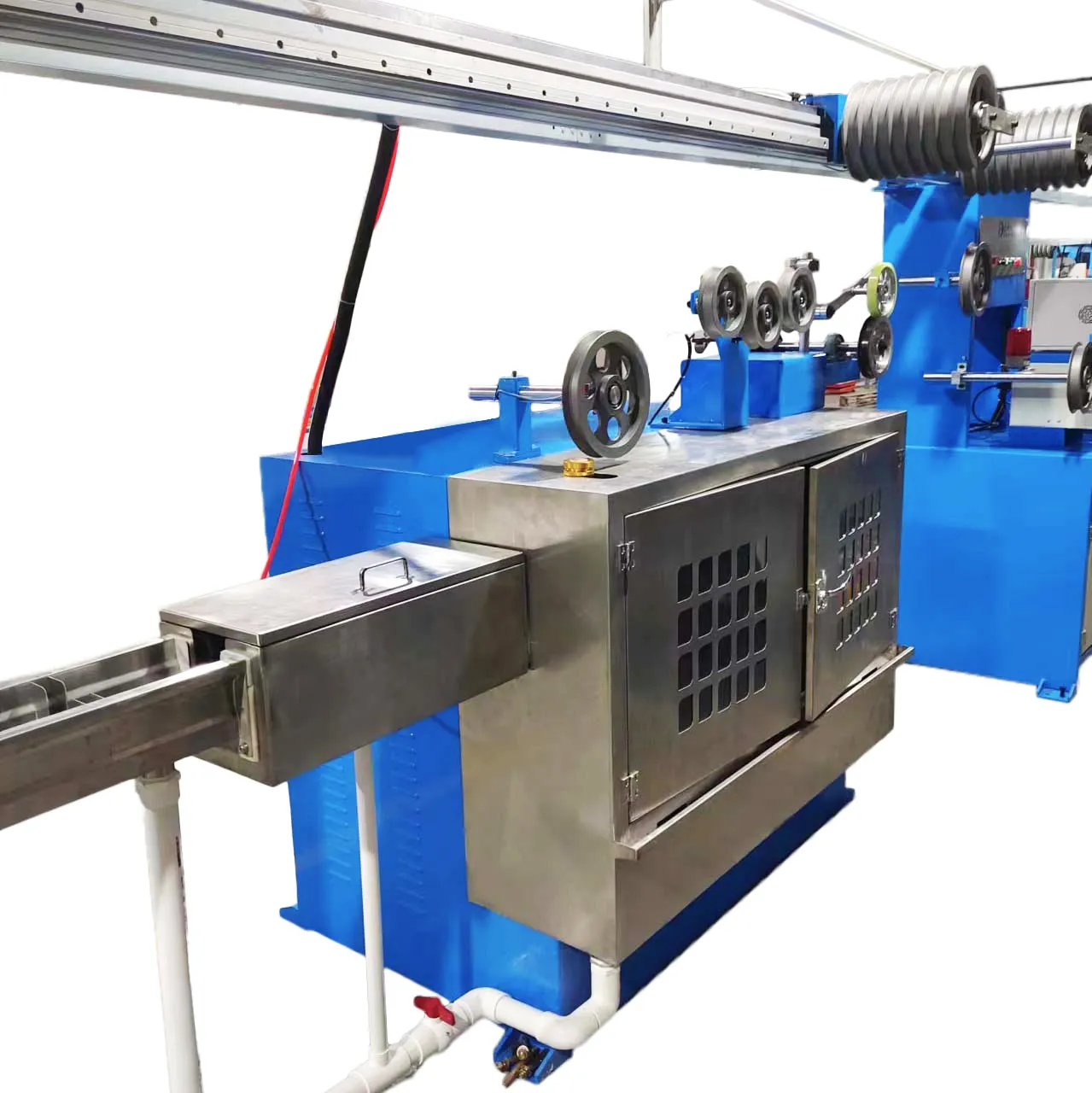

Used for the extrusion of insulation sheaths for UL electrical wires, power cables, computer wires, data cables, and high-frequency wires.

Overseas Application:

Used for single-layer wire core extrusion / foamed insulation sheath extrusion / single-layer extrusion + filled strip extrusion.

High Performance:

The special screw structure ensures efficient operation: no sticking, no chrome peeling, etc.

High Quality:

The concentricity of extruded products reaches 93-97%, product diameter tolerance: ± 0.005 mm; for foamed insulation sheaths: ± 0.008 mm; capacitance tolerance: ± 0.5 (capacitance unit not specified)

Temperature Control:

Adopts an SCR (Silicon Controlled Rectifier) power regulation device with an imported temperature control system; the machine body temperature is controlled with an accuracy of ± 1℃

Easy Operation:

Equipped with a touch-sensitive user screen, making operation simpler and more convenient.

Space Saving:

The traditional equipment layout has been optimized, reducing the overall length by more than 5 meters.

TECHNICAL SPECIFICATIONS

Can be customized :

| Machine Model | DX-Φ30 | DX-Φ40 | DX-Φ50 | DX-Φ60 |

|---|---|---|---|---|

| Wire Core Specifications | AWG36-AWG30 | AWG32-AWG28 | AWG30-AWG26 | AWG28-AWG20 |

| Product Diameter | Φ2~13 mm | Φ3~15 mm | Φ5~19 mm | Φ10~31 mm |

| Extrusion Material | HDPE (High-Density Polyethylene), Foam-PE (Foamed Polyethylene), PP (Polypropylene), PU (Polyurethane), PVC (Polyvinyl Chloride), SR-PVC (Reinforced Polyvinyl Chloride) | |||

| Screw Parameters | L/D Ratio: 26~28, Compression Ratio: 2.7-3.2, Screw Material: SACM Alloy (Aluminum-Silicon Steel Alloy) with Vacuum Heat Treatment, Surface Polishing with Grinding and Chroming | |||

| Barrel & Die Head Heating Zones | 3+2 (3 Barrel Zones + 2 Die Head Zones) | 3+2 (3 Barrel Zones + 2 Die Head Zones) | 3+2 (3 Barrel Zones + 2 Die Head Zones) | 4+2 (4 Barrel Zones + 2 Die Head Zones) |

| Heating Power | 6 kW | 8 kW | 11 kW | 15 kW |

| Extruder Power | 7.5 HP (Horsepower) | 10 HP | 15 HP | 20 HP |

| Maximum Capacity | 30 kg/h | 45 kg/h | 60 kg/h | 85 kg/h |

| Maximum Speed | 300 m/min | 400 m/min | 600 m/min | 800 m/min |

| Cooling Unit | Extended cooling unit / constant temperature cooling unit, heating power 9 kW, capacity 500 (unit not specified), length 1.7 m, with two-stage water removal device | |||

| U-Shaped Cooling Unit Length | 11 m | 11 m | 13 m | 16 m |

| Accumulation Unit Parameters | Accumulation drum with diameter Φ120~Φ180 mm, 10 fixed rollers + movable rollers, standard / inclined accumulation mechanism, length 9 m, maximum accumulated length 200 m | |||

| Drawing Power | 6 HP | 7.6 HP | 7.6 HP | 16 HP |

| Unwinder Type | Unwinder / spindleless motorized unwinder with overload protection, suitable for spools with diameter 300-500 mm | |||

| Winder Type | Dual-spindle winder, 3 HP motor with inverter speed control, operable in single or linked mode; machine stops when the counter exceeds the preset value, suitable for spools with diameter 400-500 mm | |||

OUR SERVICES

Free Pre-Sales Training:

We provide training for customers to ensure they fully master machine operation, including correct working procedures, proper maintenance methods, and troubleshooting of simple faults.

On-Site Installation Consultation:

The customer shall bear the cost of round-trip air tickets, accommodation, meals, insurance, and daily labor fees for each technician.

After-Sales Service Details:

We provide quick responses to after-sales service requests and timely fulfillment of obligations regarding (required parts) delivery.

Free warranty period: 12 months from the machine shipment date (excluding wear parts).

We charge fees for transportation costs and other related expenses.

If visas are obtained in a timely manner, our engineers are ready to travel within 24 hours for domestic trips and within 2 weeks for overseas trips.

Click here to find out more about different types of Featured Products

```