In 2026, medium to large cable factories—especially those producing EV charging cables, high-frequency data lines, power cables, and building wires—are under pressure to boost output, cut scrap, and meet stricter efficiency and quality standards. Factory owners and production managers searching for a medium to large cable factory equipment upgrade roadmap typically want a realistic, step-by-step plan: how to modernize extrusion, stranding, bunching, and pay-off/take-up systems without halting production or wasting capital. In emerging markets like India, Russia, Turkey, and Vietnam, where energy costs, labor, and raw material prices fluctuate, a smart phased approach delivers quick wins while building long-term competitiveness.

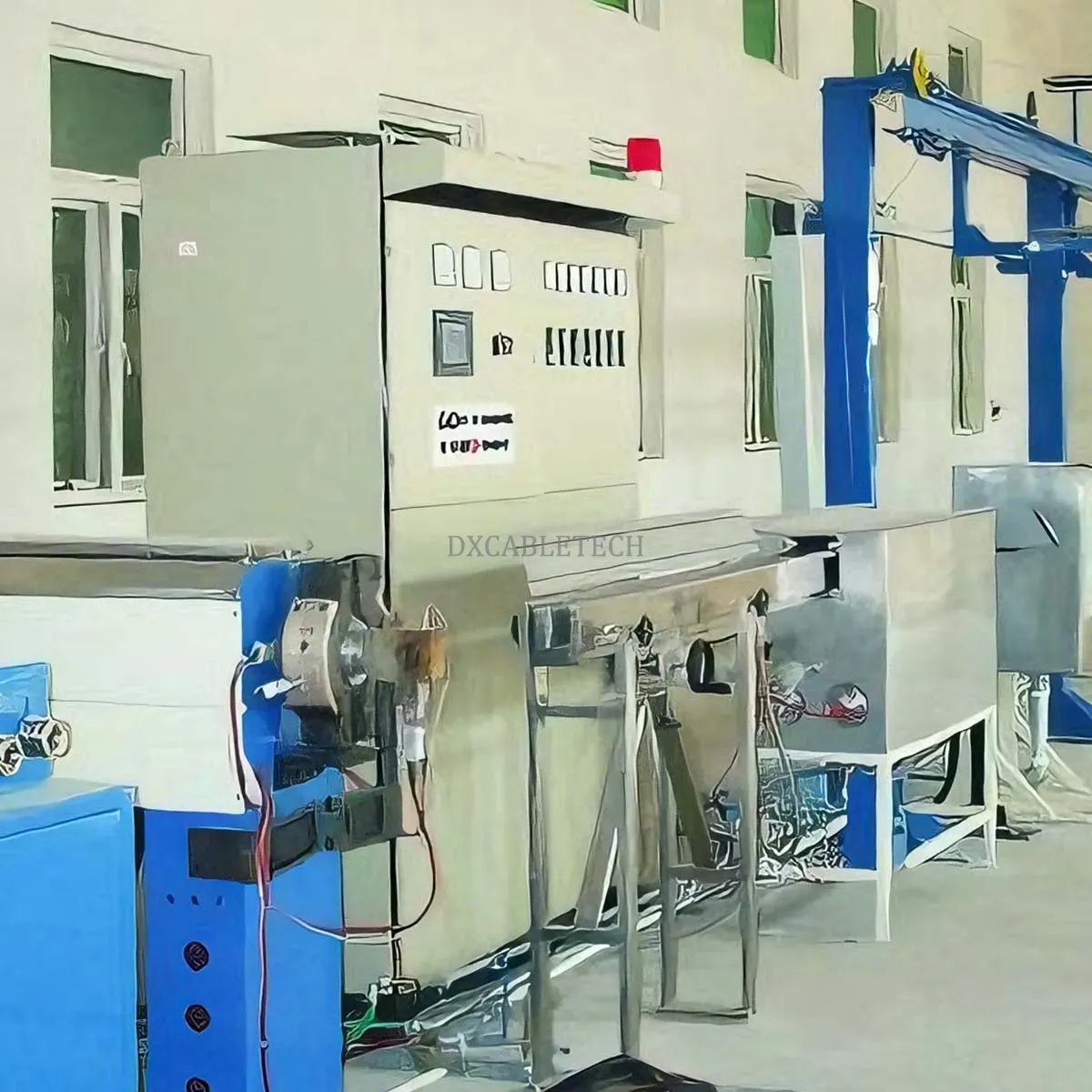

This guide outlines a practical upgrade roadmap based on real-world factory transformations, focusing on compatible, high-performance machinery like modern extruders with precise PLC control, high-speed stranding lines, and automated pay-off/take-up solutions.

Phase 1: Diagnosis & Bottleneck Mapping – Build a Clear Upgrade Foundation

Start with a thorough audit of your current setup—don't jump straight to buying new machines. Map utilization rates, downtime causes, scrap sources, and energy use across extrusion lines, stranding/bunching zones, and take-up areas.

For many medium to large plants in Turkey and Vietnam, outdated extruders cause inconsistent insulation thickness and bubbles, pushing scrap above 10%. In Russian factories, pay-off instability from voltage fluctuations leads to frequent breaks and tension issues. In India, mismatched stranding speeds create bottlenecks that limit overall line speed.

Action steps:

Collect 3-6 months of production data (output per shift, defect logs, energy meters).

Identify top 3 bottlenecks (e.g., slow stranding limiting extrusion speed, or manual pay-off causing tension swings).

Budget 8-12% of total upgrade funds here—for audits, basic monitoring tools, or consulting.

Avoid the pitfall: Skipping data and buying flashy "high-speed" equipment that doesn't fit your workflow. A solid diagnosis creates a prioritized equipment upgrade roadmap that matches your cable types (EV, data, power) and delivers measurable ROI.

Phase 2: Targeted Upgrades & Pilot Testing – Invest Smart, Scale Safely

Prioritize modular, upgrade-friendly machines that integrate easily with existing lines. Focus first on the biggest pain point.

Examples from real factories:

Upgrade an aging extrusion line to a modern PLC-controlled model (like Siemens-based systems with precise temperature and speed control) to improve concentricity on data cables and reduce defects by 15-25%.

Replace old bunching/stranding machines with high-speed double twisters or adjustable pre-twisters for better pair twisting on CAT6/7 lines or multi-core EV cables—gaining 20-30% throughput.

Add automated shaftless or multi-head pay-off/take-up systems with tension feedback to eliminate manual adjustments and cuts in high-speed runs.

Roll out in pilots: Test one upgraded section (e.g., new stranding + pay-off combo) for 2-4 months, measure output gains, scrap drop, and energy savings before full rollout. This minimizes risk—common in Indian and Turkish plants where budgets are tight.

Pitfall to dodge: All-in-one "turnkey" packages from unproven suppliers with poor local support. Choose machinery with strong after-sales (spare parts availability in your region) and compatibility for future expansions.

For more on selecting the right extruder or stranding machine, check our Cable Equipment Buying Guide 2026: Top 20 FAQs.

Phase 3: Full Integration, Training & Ramp-Up – Ensure Smooth Go-Live

Installation is where many upgrades fail—due to poor coordination or untrained staff.

Best practice: Phase the rollout (e.g., upgrade stranding and pay-off first, then extrusion, finally auxiliaries like taping or spark testers). Work with suppliers for on-site commissioning and at least 2-3 months of operator training.

In Vietnam and Russia, factories that invested in cross-training saw downtime drop 40% post-upgrade. Add IoT monitoring (basic sensors on tension, speed, temperature) for real-time alerts—preventing small issues from becoming big losses.

Budget 35-45% here: hardware, installation, training, and initial spares. Goal: Reach 90-95% of projected efficiency within 3-6 months.

Phase 4: Ongoing Optimization & Maintenance – Sustain Gains Long-Term

Upgrades aren't "set and forget." Establish preventive maintenance schedules (e.g., screw/barrel checks on extruders every 6 months, lubrication and alignment on stranding machines).

Use data from your new lines to iterate: Adjust parameters for seasonal raw material changes, or add auxiliaries like better tension boards for even tighter control.

Factories in India that followed this saw energy costs fall 10-18% and scrap stabilize below 5%. Link back to our articles on Top 25 Cable Extruder Problems and Solutions or 3 Practical Ways to Reduce Scrap Rate for ongoing tips.

Allocate 20-25% of budget to spares, software updates, and annual audits.

Final Thoughts: Your Medium to Large Cable Factory Equipment Upgrade Roadmap Starts Now

A well-executed medium to large cable factory equipment upgrade roadmap turns challenges into advantages—higher output, lower defects, better margins, and readiness for 2026+ demands in EV, data, and power cables. By phasing investments, piloting changes, and focusing on compatible, reliable machinery (extruders, stranding/bunching, pay-off/take-up), factories in Russia, India, Turkey, Vietnam, and beyond achieve sustainable growth without the usual headaches.

Ready to map your factory's path? Share your current setup or biggest bottleneck in the comments—we can offer tailored suggestions based on our turnkey solutions and real installations.