In the cable manufacturing industry—particularly on single-twist or double-twist production lines—many small and medium-sized cable factory owners and engineers frequently ask the same question: Is a pre-twist machine (Pre-Twist Machine) actually worth it? Is it just an expensive add-on that takes up space, or does it genuinely solve real production pain points, improve product quality, and boost efficiency?

As a specialized cable machinery manufacturer serving small-to-medium factories for many years, we have installed, tested, and optimized pre-twist systems on dozens of production lines. In this article, we provide a transparent, data-backed, and experience-driven answer based on actual shop-floor testing of our 630 Pre-Twist Machine, side-by-side comparisons, real customer feedback, application case studies, selection guidelines, and maintenance best practices.

Whether you're new to cable production, planning a line upgrade, or searching keywords like “pre-twist machine worth it,” “pre-twist vs no pre-twist test,” or “pre-twist benefits for power cable,” this in-depth guide will help you decide with confidence.

Core Working Principle: Why Pre-Twist Addresses a Fundamental Stranding Problem

To determine whether a pre-twist machine is useful, we must first understand the mechanical problem it solves.

During conventional stranding (single-twist or double-twist), conductor wires—especially high-tensile materials such as copper-clad aluminum (CCA), tinned copper, hard aluminum alloy, or multi-strand fine wires—develop significant residual torsional stress. When the stranded bundle is later cut, bent, or processed further, this stored energy causes:

Severe spring-back (“explosion” or “blooming” effect)

Loose structure and visible gaps between strands

Unstable lay length (pitch variation)

Oval or irregular conductor cross-section

Higher DC resistance due to reduced contact area

Poor roundness during insulation extrusion → increased scrap and customer returns

The pre-twist machine counters this by applying a controlled reverse twist (pre-twist) to individual wires or sub-bundles before they enter the main stranding cage. This pre-applied torsion neutralizes most of the forward twisting stress created during final stranding, resulting in:

Dramatically reduced spring-back after cutting

Tighter, rounder, more compact conductor

More consistent lay length

Better electrical performance and mechanical stability

This is not a “nice-to-have” feature—it is a structural solution to an inherent limitation of the stranding process, especially noticeable on medium-to-large cross-section conductors and high-resilience materials.

Real Factory Test Results: Quantifiable Improvements You Can Trust

To settle the debate once and for all, we conducted controlled side-by-side production trials using identical raw materials, the same main strander (800 mm single-twist machine), and the same operators—only varying whether the 630 Pre-Twist Machine was installed upstream.

Test Conditions

Main machine: 800 mm single-twist strander

Pre-twist unit: 630 model (max 850 RPM)

Conductor types tested:

- 7-strand power cable (1+6 structure, 2.5–10 mm²)

- Multi-layer compacted aluminum alloy conductor (1+6+12+18) for EV charging cables

Run time: 8-hour full shifts, 1,000 m samples collected per condition

Measurement instruments: laser micrometer, micro-ohmmeter, digital microscope for cross-section analysis, tension logger

Key Performance Comparison Table

| Metric | Without Pre-Twist | With 630 Pre-Twist | Improvement | Notes / Impact Area |

|---|---|---|---|---|

Maximum stable stranding speed | 650 RPM | 820–850 RPM | +26–31% | Reduced drag allows higher overall line speed |

Conductor compactness (gap %) | 8–12% gaps | 2–4% gaps | –67 to –75% | Directly affects resistance & tensile strength |

Spring-back length after cut | 15–25 cm (severe blooming) | < 3 cm (almost none) | –88 to –92% | Major reduction in customer complaints |

Extrusion first-pass yield | 88% (oval conductor issues) | 97% | +10.2% | Less rework at insulation stage |

Daily output (8 h shift) | ≈ 28,000 m | ≈ 36,000 m | +28.6% | Real throughput gain |

Scrap rate | 6–8% | 1–2% | –67 to –75% | Mainly from conductor-related defects |

Energy consumption (kWh/1,000 m) | 1.20 | 1.10 | –8.3% | Smoother stranding = lower motor load |

DC resistance variation | ±4.8% | ±1.1% | –77% | Critical for power & EV cables |

Bottom line from real production data: Adding a pre-twist machine delivered measurable gains in speed, quality, yield, and cost savings. For a medium factory producing 500,000–1,000,000 meters per year, the typical payback period falls between 6–12 months—faster if the line runs high-value products (EV, control cables, tight-compressed conductors).

Real-World Case Studies from Our Customers

Case 1: Low-Voltage Power Cable Manufacturer (Malaysia)

Problem: Frequent customer returns due to “loose conductor” and high resistance variation.

Solution: Installed 630 pre-twist upstream of an 800 mm single-twist line.

Result: Spring-back eliminated, resistance variation dropped from ±5% to ±1.2%, returns decreased by 85% within three months.

Case 2: EV Charging Cable Producer (Vietnam)

Requirement: Tight-compacted conductors to meet IEC 62893 and customer internal specs (no visible gaps, minimal spring-back).

Result: Pre-twist allowed safe speed increase from 600 to 820 RPM while achieving near-zero spring-back. Subsequent extrusion roundness improved significantly, reducing insulation thickness variation.

Case 3: Small Factory Producing Control Cables (Indonesia)

Challenge: Limited budget and space; feared pre-twist would be overkill.

Outcome: Compact 630 model (only 1.2 m footprint) integrated easily, reduced scrap from 9% to 2.5%, paid for itself in under 8 months.

These are not theoretical claims—they reflect feedback from factories we continue to support.

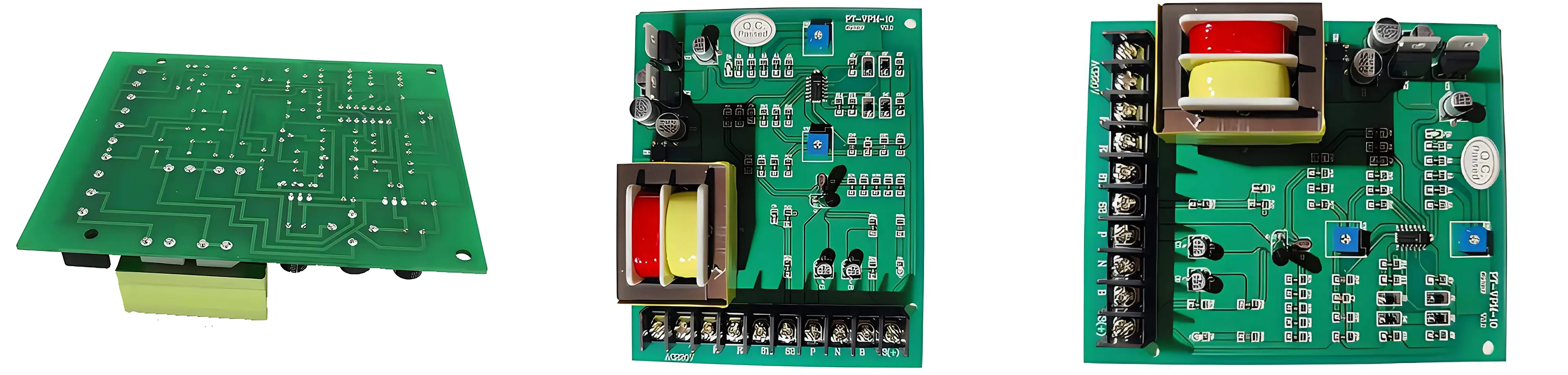

Why Our 630 Pre-Twist Machine Fits Small & Medium Cable Factories Best

We designed the 630 Pre-Twist Machine specifically for Asian SMEs with the following practical advantages:

High speed without complexity — up to 850 RPM with simple 1.5 kW AC motor + inverter control

Height adjustable centerline (±20 mm) — quick alignment with different payoff and strander heights

Modular strand distribution — 1+6 / 1+6+12 / 1+6+12+18 configurations + eyelet die holder

Large guide pulleys — 4 × Φ120 mm pulleys minimize wire surface damage

Compact & low-maintenance — footprint ≈ 1.2 m × 0.9 m, no complex PLC needed

Affordable entry price — typically 60–70% of European equivalents while delivering comparable compactness and spring-back reduction

When Do You Really Need a Pre-Twist Machine? Decision Framework

Strongly Recommended

High-resilience / springy materials (CCA, hard aluminum alloy, tinned copper, multi-strand fine wires)

Multi-layer or large cross-section conductors (>10 mm²)

Tight-compressed / compacted conductors

EV charging cables, solar cables, control cables, medium-voltage power cables

Lines where downstream extrusion or taping quality is sensitive to conductor shape

Factories receiving frequent complaints about “loose strands” or “blooming after cutting”

Can Usually Skip

Soft bare copper single-layer strands (Cat5e/6 data cables)

Small cross-section (<4 mm²) with simple 1+6 structure

Very low-end, cost-driven disposable cables

Extremely low-volume production (<200,000 m/year)

Unsure? We offer free line audits and short trial runs—contact us to discuss your specific products.

Maintenance & Optimization Best Practices (From 10+ Years of Field Experience)

Weekly: Clean guide pulleys, check bearing temperature, verify tension uniformity (±5%).

Monthly: Lubricate main shaft bearings (use high-temperature grease).

Common issue – speed fluctuation: Usually caused by motor overheating → install additional cooling fan.

Advanced tip: Integrate with our PT-24V Tension Control Board for automatic pre-twist adjustment → additional 8–12% efficiency gain.

Expected lifespan: Core components last 5–8 years under normal 5–6 day/week operation.

Looking Ahead: Pre-Twist in the 2026–2030 Cable Industry

With the rapid growth of EV infrastructure, 5G/6G backhaul cables, renewable energy wiring, and stricter quality standards (IEC, UL, GB/T), conductor precision will become even more critical. Pre-twist technology—once considered a luxury—is quickly becoming standard even among mid-tier producers. We are already developing IoT-enabled versions with real-time tension monitoring and predictive maintenance alerts.

Conclusion: Pre-Twist Is No Longer Optional for Serious Quality & Efficiency

After years of side-by-side testing, customer implementations, and continuous improvement, the verdict is clear:

A pre-twist machine is genuinely useful—and often essential—when you produce high-resilience conductors, multi-layer structures, or quality-sensitive cables. It reduces scrap, increases line speed, improves downstream yield, lowers customer complaints, and typically pays for itself within one year.

We welcome factory visits, video demonstrations, and open discussions—no pressure, just transparent engineering advice.

(Last update: January 2026 – All data based on documented factory trials and customer-verified results.)