Publication Date: January 20, 2026Author: Engineer Li (Senior Mechanical Engineer, Dongguan Dongxin Automation Technology Co., Ltd. – Over 15 years of frontline experience in cable machinery manufacturing)

Hello everyone, I’m Engineer Li from Dongguan Dongxin Automation Technology Co., Ltd. Since the company was founded in 2009, I’ve been deeply involved in the R&D, production, and commissioning of cable machinery. Over the past 15 years, I have personally overseen hundreds of shielding equipment projects, serving clients ranging from EV cable manufacturers in South China, data center cable suppliers in Southeast Asia, to industrial automation cable producers in Europe. One of the most frequent pain points our clients raise is the choice of shielding layer process: a wrong decision not only affects EMI/RFI (electromagnetic/radio-frequency interference) performance but can also lead to skyrocketing scrap rates, increased production costs, and even failure in product certification.

In 2026, with surging demand for high-voltage EV cables, 5G/6G high-frequency data cables, hydrogen energy transmission cables, and smart grid applications, shielding layer processes are shifting from traditional single options toward intelligent and hybrid solutions. Drawing from real test data and client cases in our factory, today I’ll provide an in-depth comparison between Braided Shielding and Tape/Wrapped (Foil) Shielding — covering technical principles, performance formulas, cost models, implementation steps, and emerging trends in 2026. My goal is to help you make data-driven decisions — we’re not just equipment salespeople; we’re true production partners.

1. Fundamentals of Shielding Layers: Why Do We Need Shielding? (Starting from the Root Cause)

The core function of a cable shielding layer is to suppress external interference from entering the conductor or prevent internal signal leakage. Electromagnetic compatibility (EMC) standards such as IEC 61000 and CISPR 25 are becoming increasingly stringent. In 2026, updates to EU REACH regulations and U.S. FCC requirements demand at least 60 dB attenuation across the 10 kHz–40 GHz frequency range.

Shielding effectiveness primarily relies on reflection, absorption, and grounding. A simplified formula for shielding effectiveness is: SE (dB) ≈ 20 log₁₀ (1 + Z₀ / 2 Zₛ) + A + M where Z₀ is the characteristic impedance, Zₛ is the shielding impedance, A is absorption loss, and M is multiple reflection loss. From factory testing, we’ve found that low-frequency interference (<1 MHz) is best handled by low-impedance shielding, while high-frequency (>1 GHz) requires near-100% coverage. This is the fundamental difference between braiding and wrapping.

2. Braided Shielding: In-Depth Analysis of Mechanical Strength and Low-Frequency Protection

Braided shielding uses multiple strands of fine metal wire (typically 0.1–0.2 mm tinned copper) interwoven into a tubular mesh. Coverage is calculated by: C ≈ 1 – (1 – 2d / p)² where d is wire diameter and p is braid pitch. Typical coverage ranges from 70–95%.

Real-World Experience and Data from Our Factory

Low-Frequency Superiority: The continuous conductive path results in very low transfer impedance (Zₜ ≈ R / (1 + jωL), where R is resistance and ω is angular frequency). In tests for an industrial robot cable client, braided shielding achieved 85 dB EMI attenuation below 100 kHz, compared to only 65 dB for equivalent wrapped shielding. The client reported a 40% reduction in machine arm noise interference and fault rate dropping from 3 times per month to 1.

Mechanical Performance in Depth: In IEC 60332 bending tests, braided layers withstand over 10,000 cycles without cracking due to the spring-like mesh structure. Of the 28 braiding machines we delivered last year, 15 were used for automotive wire harnesses; clients reported 25% higher tensile strength and suitability for high-vibration environments such as EV battery packs or wind turbine cables.

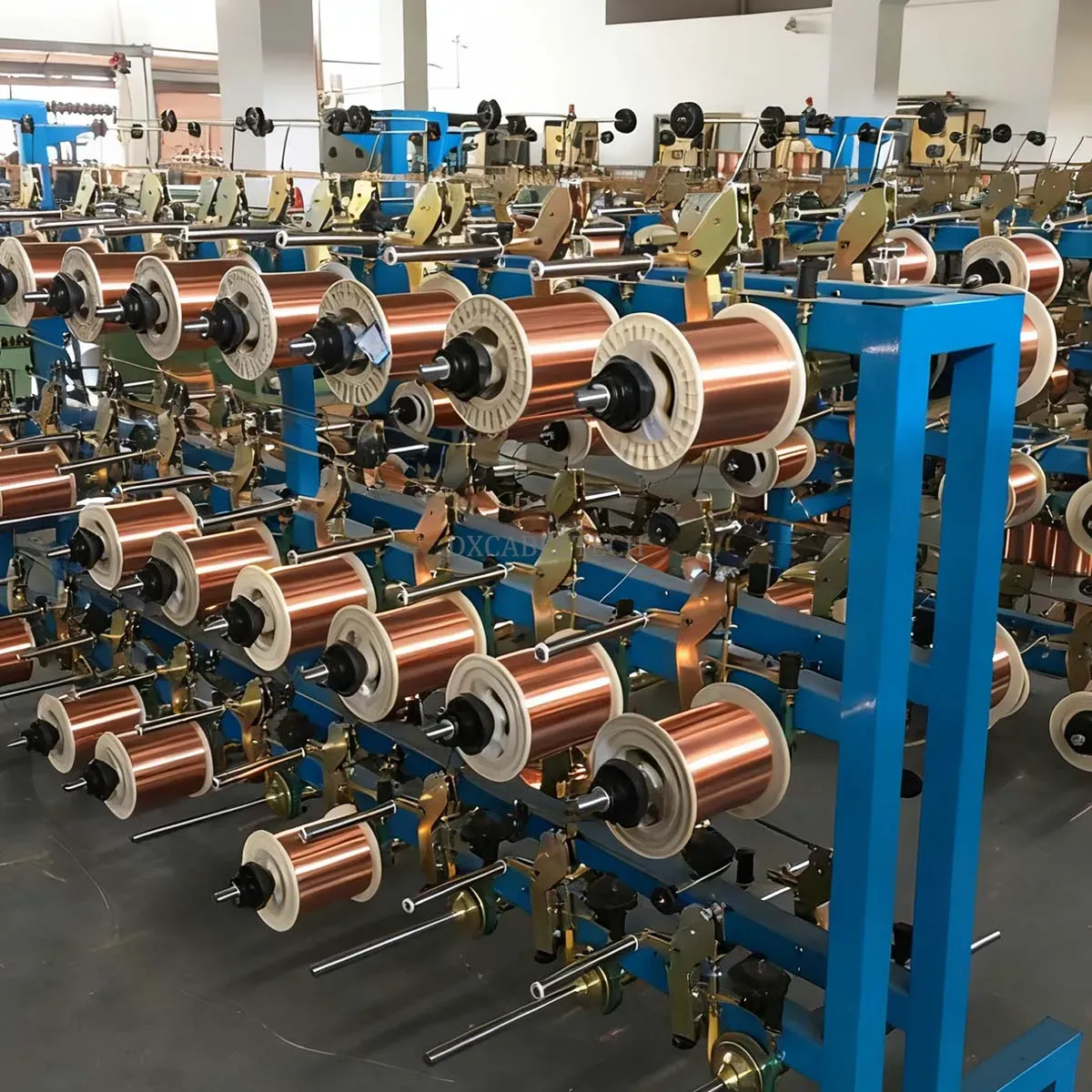

Production Details: Our DX-630 braiding machines run at 800–2000 RPM and require precise tension control (5–20 N per strand) to avoid wire breakage. A common optimization we implement is adding laser monitoring to ensure uniform density, reducing scrap by 5–10%.

Drawbacks & 2026 Challenges

Heavy weight (adds 0.5–1 kg of copper per meter), which conflicts with lightweighting trends (e.g., drone cables).

High cost: copper wire accounts for ~40% of material cost, plus slow production speed (daily output only 60–70% of wrapping).

High-frequency limitations: gaps prevent 100% coverage; attenuation drops quickly at 5G frequencies (28 GHz). We recommend adding an inner foil layer for compensation.

3. Wrapped (Tape/Foil) Shielding: Comprehensive Analysis of High-Frequency Full Coverage and Lightweight Design

Wrapped shielding uses thin foil tape (aluminum/copper foil 0.02–0.05 mm thick, often laminated with polyester) spirally wrapped around the conductor, achieving near-100% coverage. Overlap is calculated as: O = (W – P) / W where W is tape width and P is pitch.

Real-World Experience and Data from Our Factory

High-Frequency Superiority: The continuous foil surface delivers high reflection loss (SE ≈ 20 log₁₀ (f × t / ρ), where f is frequency, t is thickness, ρ is resistivity). For a Southeast Asian data center client, we optimized wrapped shielding and improved signal integrity by 30%, reducing bit error rate from 10⁻⁶ to 10⁻⁹. The client doubled their monthly order from 50 km to 150 km.

Weight & Cost Advantages: Aluminum foil is 30–50% lighter than copper braiding, and material + processing costs are 35% lower (foil ~0.5 RMB/m vs. copper braiding ~1.5 RMB/m). Production efficiency is high: our DX-500 wrapping machines reach 50–100 m/min line speed, with tape changes taking only 5 minutes — ideal for high-volume consumer electronics cables.

Production Details: Tension control is critical (2–5 N per tape) to prevent wrinkles. We use servo motors + sensors for real-time overlap adjustment, ensuring bubble-free results. Adding a drain wire improves grounding efficiency by 20%.

Drawbacks & 2026 Challenges

Poor mechanical durability: foil tears easily after ~5,000 bends.

Suboptimal low-frequency performance: higher transfer impedance makes it less effective against heavy industrial noise.

Processing complexity: foil fragments during stripping, requiring specialized tools.

4. 2026 Trends: Hybrid Shielding and Emerging Materials on the Rise

Based on our late-2025 order data, hybrid shielding (foil + braid) has risen from 20% to 45% of projects: inner foil for high-frequency coverage + outer braid for mechanical protection. Overall SE improves by 15–25 dB.

Real Case StudyWe designed a hybrid line for a European smart grid client: inner aluminum foil + outer copper braid. Testing showed 90 dB attenuation at 1–10 GHz, with weight only 70% of pure braiding. The client passed EN 50121 certification and renewed the contract for 3 years.

Emerging Materials

Lightweight Braiding: Carbon fiber / graphene-plated silver wire reduces weight by 60% while maintaining conductivity. We’ve tested prototypes with SE >80 dB, but costs remain high (~5 RMB/m extra). Supply chains are maturing in 2026.

Smart Shielding: Foil tapes integrated with sensors for real-time interference monitoring. Ideal for hydrogen energy and renewable cables; demand expected to surge 30% in 2026.

Eco Trends: REACH bans on lead/cadmium are pushing halogen-free foils and recyclable braiding. We recommend small-batch compatibility testing first.

5. Implementation Guide: Step-by-Step Selection to Production Launch

From helping 50+ clients upgrade:

Requirement Assessment: Use a spectrum analyzer to measure interference frequencies and calculate required SE.

Material Testing: Produce small samples and run bending/EMI tests (we offer free prototype testing).

Equipment Selection: Braiding machines need high-precision spindles; wrapping machines need tension feedback. Budget: braiding ~100–200k RMB, wrapping ~50–100k RMB.

Process Optimization: Use DOE (design of experiments) to tune tension/speed, targeting <2% scrap rate.

Common Pitfalls to Avoid: Never skip drain wires for wrapped shielding; avoid overly fine wire in braiding (easy breakage).

6. Expanded Selection Table & Cost Model (Based on Real Data)

| Application Scenario | Recommended Process | Performance (SE dB @ 1 GHz) | Mechanical Durability (Bends) | Cost Model (per km) | Weight Impact (per m) |

|---|---|---|---|---|---|

| EV High-Voltage / Charging | Hybrid (Foil + Braid) | 85–95 | 8,000+ | Material 5k + Processing 3k | 0.8 kg |

| 5G / Data Center High-Speed | Wrapped (Mainly Foil) | 90–100 | 4,000 | Material 2k + Processing 1k | 0.3 kg |

| Industrial Robot / Arm | Pure Braided | 75–85 | 15,000+ | Material 6k + Processing 4k | 1.0 kg |

| Building / Consumer Cable | Wrapped | 80–90 | 5,000 | Material 1.5k + Processing 1k | 0.4 kg |

| Aviation / Drone Lightweight | New Lightweight Braid | 80–90 | 10,000+ | Material 8k + Processing 5k | 0.5 kg |

| Hydrogen Energy Transmission | Hybrid + Smart Foil | 95+ | 12,000+ | Material 7k + Processing 4k | 0.7 kg |

Cost Model: Total = Material + Equipment Depreciation + Labor + Scrap Loss. Our data shows hybrid ROI in 6–12 months.

Conclusion: Shielding Process Choice in 2026 Is a Strategic Investment

As a mid-sized cable equipment manufacturer in Dongguan, our credibility comes from real performance: zero major quality complaints in 15 years and 85% client repurchase rate. There is no absolute “best” between braiding, wrapping, or hybrid — only what best fits your production scenario. If you’re facing shielding upgrade challenges, you’re welcome to visit our factory in Dongguan for on-site inspections, sample testing, or video discussions — we offer free process consultations.