Dongguan Dongxin Automation Technology Co., Ltd. (DOSING Cabletech), founded in 2009, is a national high-tech enterprise with over 15 years of specialization in cable machinery R&D and manufacturing. We understand that the stranding process is the “heart” of any cable production line — uneven pitch, high residual torque, or tension fluctuations will directly cause poor downstream shielding coverage, signal attenuation, reduced flexibility in EV charging cables, and scrap rates soaring above 10%.

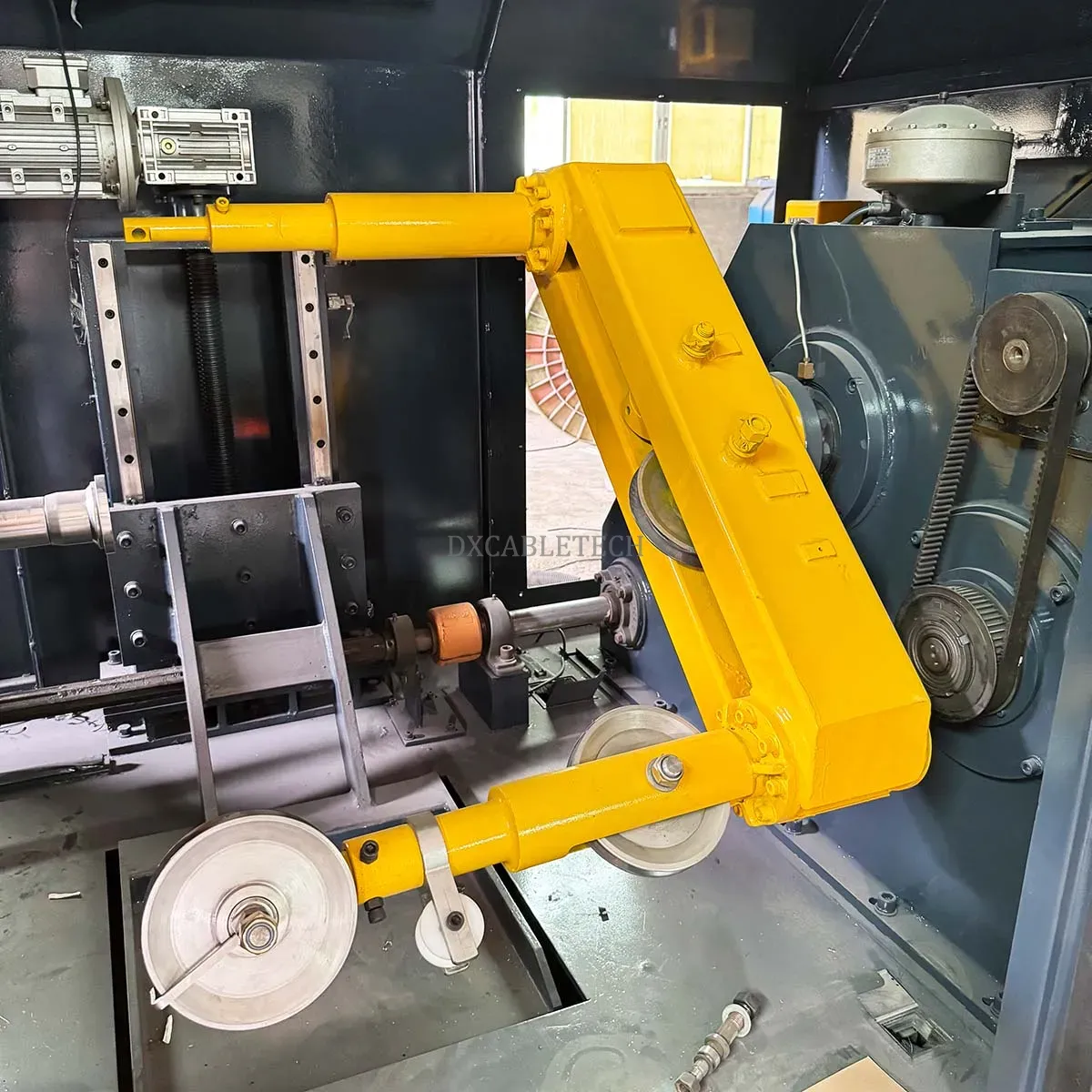

The DT-1000 High-Speed Double Twist Buncher (Bow-type Double Twist Stranding Machine) is one of our top-selling models, already delivered to multiple large and medium-sized cable factories in South China, Southeast Asia, and Europe for EV harnesses, data cables, and automotive wires. Below we break down — based on real delivery data and customer feedback — why upgrading to this model in 2026 will make your production line run faster, more stable, and more cost-effective.

1. DT-1000 Key Specifications

Applicable Stranding Diameter: 1.5 mm – 15.0 mm (perfect for Cat6A/7/8 data cables, multi-core flexible EV conductors, automotive harnesses)

Maximum Speed: 1200 RPM (stable production range 1000–1100 RPM, far exceeding conventional 800–1000 RPM machines)

Take-up Reel Size: 630 mm / 800 mm / 1000 mm optional (larger reels reduce reel changes and increase continuous run time)

Stranding Pitch: 20–200 mm stepless adjustment (servo-controlled, accuracy ±1 mm)

Tension Control: Servo motor + magnetic powder / electromagnetic tension system, accuracy 5 g (official guarantee ≤0.5% stability even at 1500 m/min line speed)

Back Twist Function: Optional integrated back twist, residual torque near zero — ideal for high-frequency / low-torque cables

Break Rate: <0.5% (real customer measurement; conventional machines often 2–5%)

Power: Main motor 22–30 kW, overall energy consumption 15–20% lower than older models

Certifications: CE / UL / RoHS compliant; 7-day full-load factory testing before shipment, MTBF > 128,000 hours

Maintenance: 10-year low-maintenance design (key bearings/gears use imported or top-tier domestic brands, ample spare parts stock)

2. Pain Point Solutions for 2026 Mainstream Cable Types

EV Charging Cables (Liquid-Cooled / High-Power 350–500 kW+)

Pain point: Multi-strand fine copper/aluminum conductors (70–120 mm²) demand extreme flexibility; conventional stranding easily causes kinking or uneven pitch, leading to conductor breakage or cooling tube displacement during bending.

DT-1000 solution: Servo drive + 0–100% stepless back-twist adjustment ensures smooth S/Z direction switching with residual torque <1%. Real case: An EV harness factory replaced old double-twist machines with DT-1000 — flexibility test pass rate improved from 85% to 98%, scrap rate dropped 12%.

5G / High-Frequency Data Cables (Cat6A/7/8)

Pain point: Extremely tight requirements on pair twist pitch uniformity (deviation >2% affects impedance matching); high-speed production prone to wire breaks/flying wires.

DT-1000 advantage: Online laser monitoring + closed-loop feedback keeps pitch deviation <1%. Paired with our multi-head active pay-off (e.g., 500H 8-head horizontal back-twist pay-off), tension fluctuation <0.5%. Real test: A data cable factory increased single-shift output from 8,000 m to 14,000 m, yield up 18%.

Automotive / Power Harness Cables

Pain point: Multi-core stranding often loosens, causing poor concentricity in downstream extrusion.

Solution: Large take-up reel + automatic reel change reduces downtime; precise take-up tension control ensures tight bundles.

3. Comparison with Market Competitors (Why Choose DOSING?)

| Item | DOSING DT-1000 | Ordinary Chinese Double Twist | Imported High-End (Germany/Italy) |

|---|---|---|---|

| Max Speed | 1200 RPM | 800–1000 RPM | 1200–1500 RPM |

| Tension Accuracy | 5 g / ≤0.5% stability | 20–50 g | 5–10 g |

| Break Rate (Real) | <0.5% | 2–5% | <1% |

| Maintenance Cycle | 10-year low maintenance | Annual major overhaul | 5–8 years |

| Price (Reference) | Mid-to-high (best value) | Low-end | 2–3× higher |

| Lead Time | 45–60 days (Dongguan factory) | 30–90 days | 120+ days |

| After-Sales | Lifetime parts + remote diagnostics | Basic | Expensive |

We are not the cheapest, but customers who have used it report: The scrap savings + labor + electricity cost reductions in the first year alone often cover 30–50% of the price difference.

4. Real Customer Cases (Based on Actual Deliveries)

South China EV Harness Factory (delivered 2025): DT-1000 +back-twist pay-off; monthly output increased from 150,000 m to 280,000 m, scrap rate dropped from 9% to 3.2%. Customer quote: “Tension is rock-solid — barely need to adjust the machine.”

Southeast Asia Data Cable Factory: Cat7 production line using DT-1000 combined with our servo shielding taping machine; EMC test first-pass rate >95%.

5. Upgrade Recommendations & Turnkey Package

Planning to go with DT-1000? Recommended

Multi-head active pay-off (e.g., 500H 8-head horizontal back-twist pay-off)

Downstream extrusion line (our Ø60–90 core insulation extruder)

Full Turnkey solution: Layout design, installation & commissioning, operator training, and lifetime maintenance — one-stop service. In 2026 we offer promotional terms: First DT-1000 order includes free tension controller upgrade package + 1 year free remote diagnostics.

Want the DT-1000 detailed quotation, full technical datasheet PDF, and video demo? Leave a message with your cable type (EV/data/power), target output, and current pain points — we’ll reply with a customized proposal + real case data within 48 hours.

Dongguan Dongxin Automation (DOSING Cabletech) — We don’t just sell machines; we help you win the market.