On high-speed wire and cable production lines, the payoff and take-up equipment functions like the heart, pumping the lifeblood through the entire production process. Yet, few truly understand the fundamental differences between these "twin brothers."

Inside DOSING wire and cable manufacturing plant, a reel of copper wire is mounted onto a frame, beginning its journey from raw material to finished product. The pay-off unit steadily releases the wire material. After passing through multiple processes like drawing, stranding, and insulation, the take-up unit at the opposite end neatly winds the finished product onto a spool.

This seemingly basic mechanical duo forms the backbone of the global cable industry, estimated to be worth hundreds of billions of dollars.

In cable production, payoff machines are separate but integral elements.

Whats the diffrence between pay-off and take-up machines?

Payoff Machines : As Line Starters

Payoff machines are used to start a production line by holding large reels of raw cable or cable reel payoff. They are designed to maintain precise tension on the back of the material, preventing breaks and tangles. Too much tension can cause breaks while too little tension will result in slack. As reels empty they adjust tension constantly with dancer arms that provide real-time tension control, as well as sensors alerting them when reels near empty. Dancer arms provide real-time control of tension, and sensors warn when reels are near empty to prevent breaks.

Take-up Machines: The Linefinisher

A take-up machine adds the final touches to your line by winding the cable onto new reels in perfect tension. A tension that is too loose can cause the rolls to become unstable ("telescoping") while a tension that is too tight will damage the cables. Variable frequency drives slow down the rotation as reels fill to maintain a constant winding speed. Automated dual spindle systems allow for reel changes to be made instantly without stopping production.

Why the Distinction Matters between pay-off and take-up machines?

Confusing pay off and take off (take-up) machines leads to operational inefficiencies and quality issues:

Incorrect Payoff: Causes feed instability, tension spikes/sags, wire breakage, or stretching – ruining product quality and halting production.

Incorrect Take-Up: Results in poor winding (loose wraps, telescoping, edge damage), making handling, shipping, and unwinding difficult, potentially damaging the cable.

Modern Advancements of Dosing Cabletech

Modern advancements of Dosing Cabletech offer real benefits: auto-tensioning, low reel alerts, and quick-loading systems are just a few.

Take-ups for advanced reels: robotic reel handling, precise servo guided winding.

Integrated control: The PLCs in the payoff and take up machines allow for seamless communication between them.

DOSING has made many optimizations and improvements to the performance of payoff machine such as:

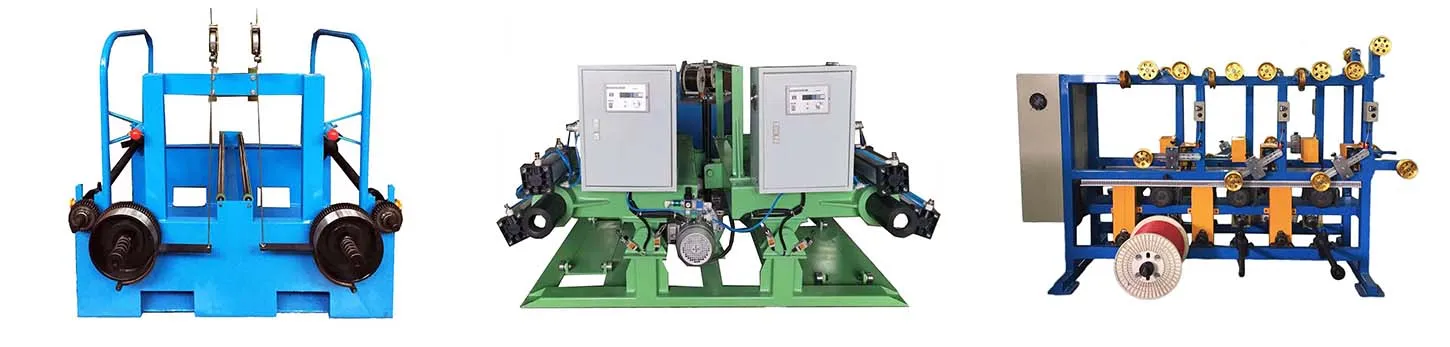

DOUBLE SHAFT WIRE EXTRUSION PAY-OFF

20-30% greater efficiency (fewer breaks/changeovers )

DUAL-STATION SHAFTLESS PAY-OFF STAND

Ultra-Reliable Automation with Fail-Safe Protection.

MULTI-POSITION TENSION PAYOFF

Reduce costs (energy and labour savings)